Pinewood Derby Axle Preparation Study

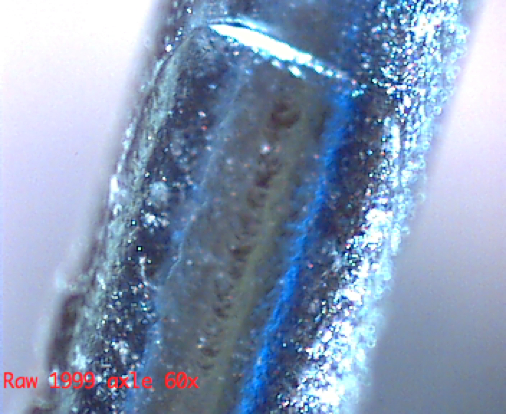

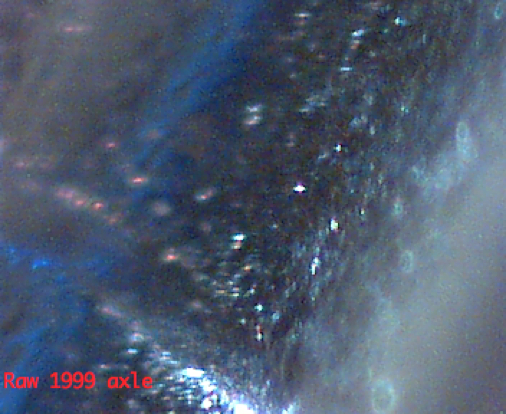

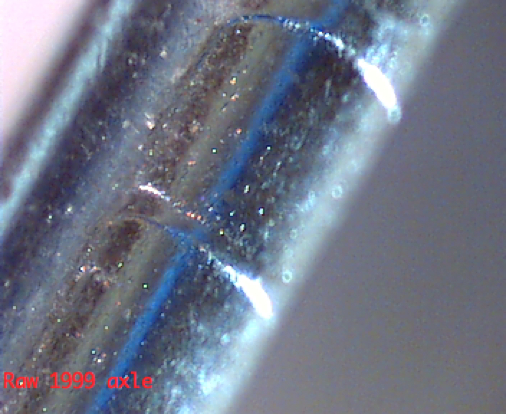

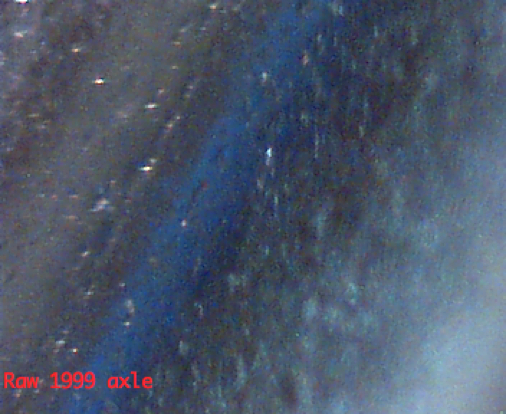

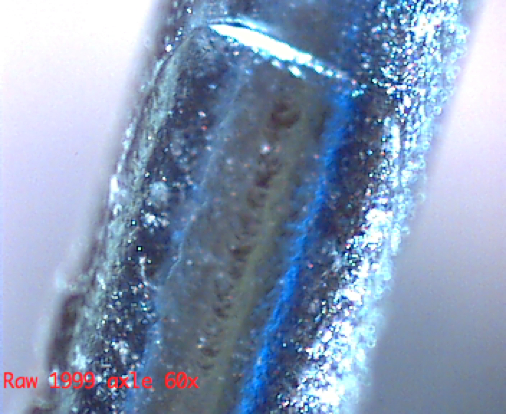

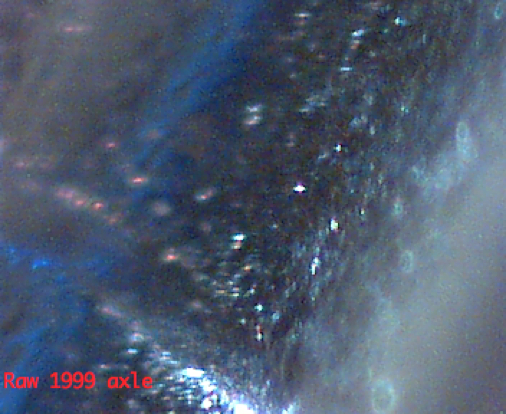

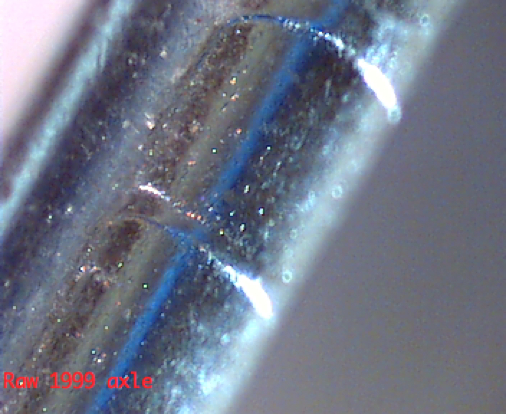

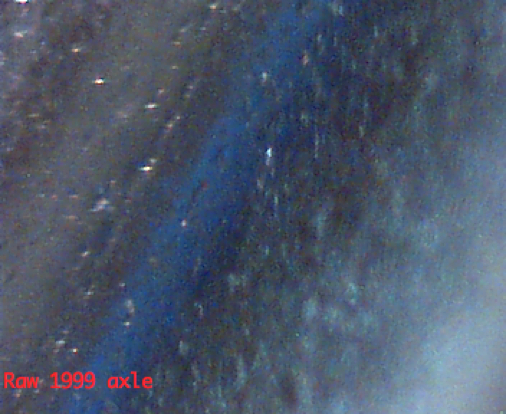

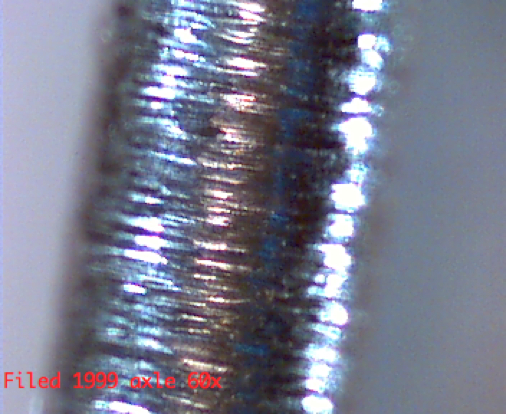

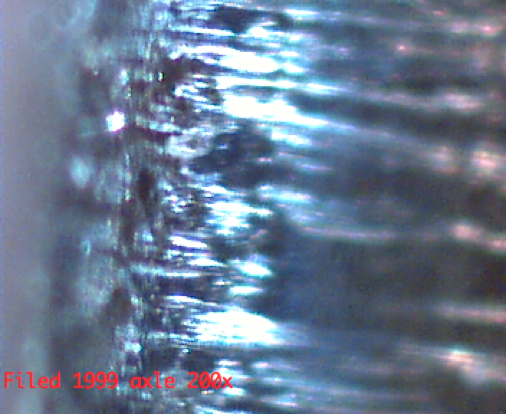

This page contains some captured microscope images of pinewood derby

axles under different preparations.

The microscope is an Intel QX-3, and the images shown here are all

taken at either 60x (on the left) or 200x (on the right) magnification.

First, these images of a "raw" axle, as it comes out of the box.

File Plus Sanding

This axle was dressed with an ordinary metal file in order to remove

burrs and crimp marks; here is the result:

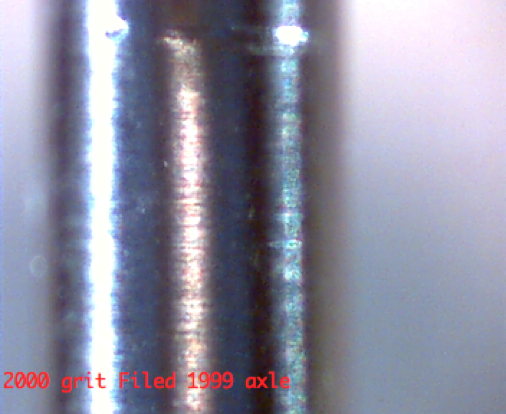

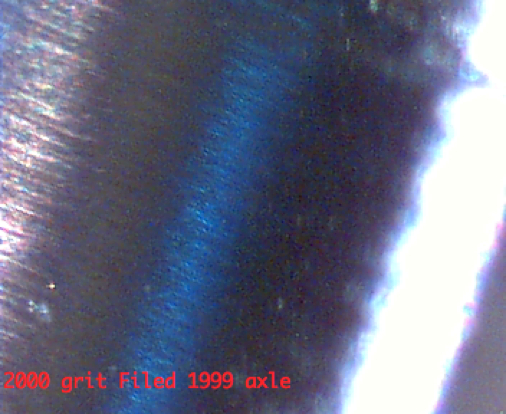

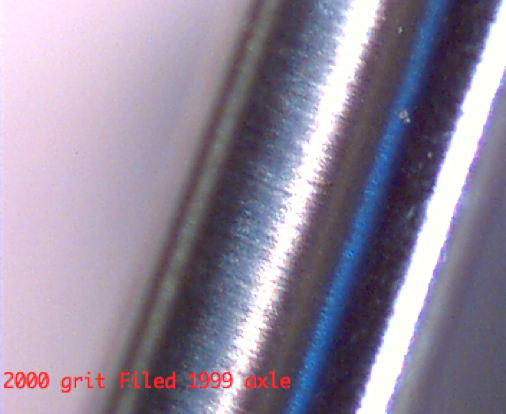

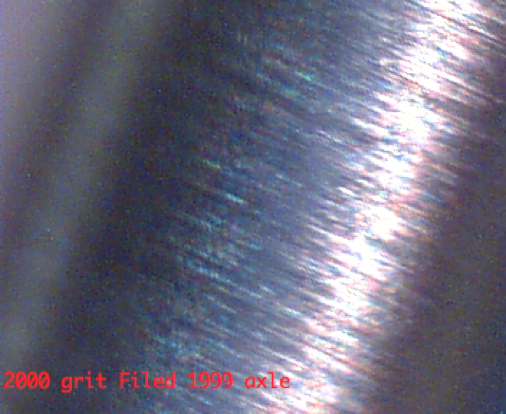

After filing, wet sanding at grits of 320, 400, P600, P800, 1000, 1500,

and 2000 was applied. After each grade of sanding, a cotton cloth

was used to clean the slurry from the axle. When this process was

completed, the resulting axle looked like this. (Images after

each sanding step are available here.)

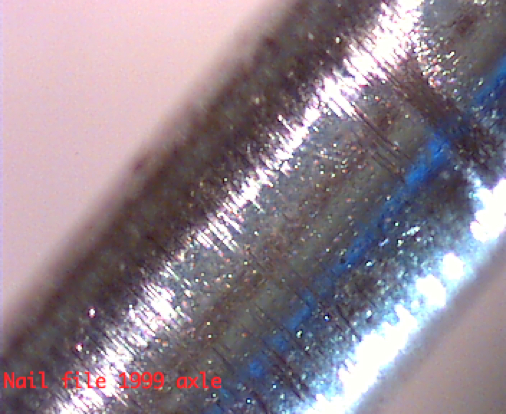

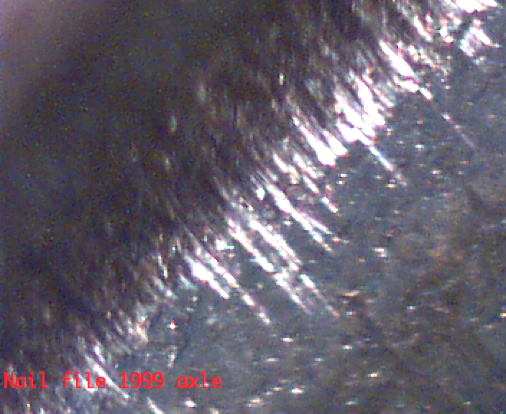

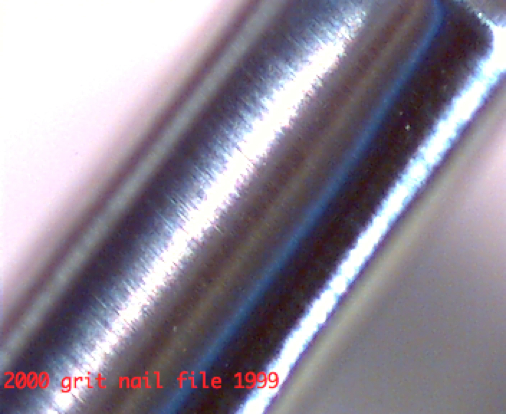

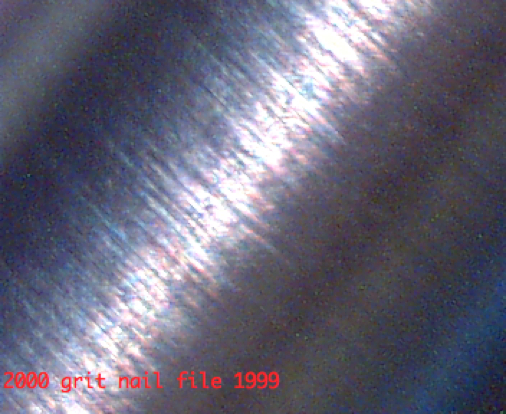

Nail File Plus Sanding

This axle was dressed with a La Crosse "sapphire nail file," rather

than an ordinary metal file. The relatively fine abrasives

yielded a slightly cleaner result:

Once again, wet sanding at grits of 400, P600, P800, 1000, 1500,

and 2000 was applied. (After examining the results from the file,

320 grit was deemed too coarse to bother with.) After each grade

of sanding, a cotton cloth

was used to clean the slurry from the axle. The result, shown

here, is virtually identical to the result of using a file.

(Images after

each sanding step are available here.)

Lapping Film

Some follow-up experiments using 3M lapping film here.

Other Axle Treatments

We've mostly used sandpaper for axle polishing, but other materials are

possible. Results of using pumice and jeweler's rouge on a used

axle are shown here.